The processes are very varied. This is due to the multitude of experimental quantities, the different nature of the measurement of quantities, the different requirements for measurement accuracy, and others.

The most common classification of types of measurements depends on the method of processing experimental data. In accordance with this classification, measurements are divided into direct, indirect, joint and cumulative.

Direct measurement

Direct measurement is the measurement at which the desired value physical quantity is found directly from the experimental data as a result of comparing the measured value with standards.

- measuring length with a ruler.

- measurement of electrical voltage with a voltmeter.

Indirect measurement

Indirect measurement- a measurement in which the desired value of a quantity is found on the basis of a known relationship between this quantity and the quantities subjected to direct measurements.

- the resistance of the resistor is found on the basis of Ohm's law by substituting the values of current and voltage obtained as a result of direct measurements.

Joint measurement

Joint measurement- simultaneous measurement of several non-identical quantities, to find the relationship between them. In this case, the system of equations is solved.

- determination of the dependence of resistance on temperature. At the same time, non-similar quantities are measured, and the dependence is determined based on the measurement results.

Cumulative dimension

Cumulative dimension- simultaneous measurement of several quantities of the same name, in which the desired values of the quantities are found by solving a system of equations consisting of the resulting direct measurements of various combinations of these quantities.

- measurement of the resistance of resistors connected by a triangle. In this case, the resistance value between the vertices is measured. Based on the results, the resistances of the resistors are determined.

Wikimedia Foundation. 2010 .

See what "Direct measurement" is in other dictionaries:

direct measurement- Measurement, in which the desired value of the physical quantity is obtained directly. Note. The term direct measurement originated as the opposite of the term indirect measurement. Strictly speaking, the measurement is always direct and is considered as ... ... Technical Translator's Handbook

direct measurement- 3.5 direct measurement: Measurement by which individual components and/or groups of components are determined by comparison with identical components in the GSO. Source … Dictionary-reference book of terms of normative and technical documentation

Direct measurement- 19) direct measurement measurement, in which the desired value of the quantity is obtained directly from the measuring instrument; ... Source: the federal law dated 06/26/2008 N 102 FZ (as amended on 07/28/2012) On ensuring the uniformity of measurements ... Official terminology

direct measurement- tiesioginis matavimas statusas T sritis Standartizacija ir metrologija apibrėžtis Matuojamojo dydžio vertės nustatymas tiesiog iš eksperimento duomenų. pavyzdys(iai) Kūno masės matavimas skaitmeninėmis svarstyklėmis. atitikmenys: engl. direct… … Penkiakalbis aiskinamasis metrologijos terminų žodynas

direct measurement- tiesioginis matavimas statusas T sritis fizika atitikmenys: angl. direct measurement vok. direkte Messung, f rus. direct measurement, n; direct measurement, n pranc. mesure directe, f … Fizikos terminų žodynas - This term has other meanings, see Measuring (meanings). Measurement is a set of operations to determine the ratio of one (measured) quantity to another homogeneous quantity, taken as a unit, stored in a technical ... ... Wikipedia

Measurement- an operation by which the ratio of one (measured) quantity to another homogeneous quantity (taken as a unit) is determined; a number expressing such a ratio is called the numerical value of the measured quantity. ... ... Encyclopedic Dictionary of Metallurgy

Indirect measurements are those measurements in which the desired value of a quantity is found by calculation based on the measurement of other quantities related to the measured quantity by a known relationship

A \u003d f (a 1, ..., a m).(1)

The result of indirect measurement is an estimate of the quantity A, which is found by substituting into formula (1) estimates of the arguments and i .

Since each of the arguments a i is measured with some error, then the problem of estimating the error of the result is reduced to To summation of measurement errors of arguments. However, a feature of indirect measurements is that the contribution of individual errors in the measurement of arguments to the error in the result depends on the form of the function A.

To estimate errors, it is important to subdivide indirect measurements into linear and non-linear indirect measurements.

For linear indirect measurements, the measurement equation has the form

Where b i - constant coefficients at arguments and i .

Any other functional dependencies refer to non-linear indirect measurements.

The result of a linear indirect measurement is calculated by formula (2), substituting the measured values of the arguments into it.

Argument measurement errors can be set by their boundaries Da i or trust boundaries Da(P) i with confidence R i .

With a small number of arguments (less than five), a simple estimate of the result error DA is obtained by summing the marginal errors (ignoring the sign), i.e. boundary substitution D a 1, D a 2, ... , D a m into an expression

Da 1 + Da 2 + ... + Da m.(3)

However, this estimate is overestimated, since such summation actually means that the measurement errors of all arguments simultaneously have a maximum value and coincide in sign. The probability of such a coincidence is extremely small and practically equals zero.

To find a more realistic estimate, one proceeds to the statistical summation of the errors of the arguments.

Nonlinear indirect measurements are characterized by the fact that the results of measurements of the arguments are subject to functional transformations. But, as shown in probability theory, any, even the simplest functional transformations random variables, lead to a change in the laws of their distribution.

With a complex function (1) and, in particular, if it is a function of several arguments, finding the law of distribution of the result error is associated with significant mathematical difficulties. Therefore, in non-linear indirect measurements, interval estimates of the error of the result are not used, being limited to an approximate upper estimate of its boundaries. The approximate estimation of the error of nonlinear indirect measurements is based on the linearization of function (1) and further processing of the results in the same way as the calculation is performed for linear measurements.

In this case, the expression for the total differential of function A will look like:

As follows from the definition, the total differential of a function is the increment of a function caused by small increments of its arguments.

Taking into account that the measurement errors of the arguments are always small compared to the nominal values of the arguments, we can replace in (4) the differentials of the arguments da i on measurement errors Da i, and the differential of the function dA- on the error of the measurement result DA. Then we get

Having analyzed dependence (5), we can formulate a number of relatively simple rules for estimating the error of the result in indirect measurements.

Rule 1 Errors in sums and differences.

If a 1 And a 2 measured with errors Da 1 And Da 2 and the measured values are used to calculate the sum or difference A \u003d Da 1 ± Da 2, then the absolute errors are summed (ignoring the sign).

Direct measurements

Direct measurement

Direct measurement- this is a measurement in which the desired value of a physical quantity is found directly from experimental data as a result of comparing the measured quantity with standards.

- measuring length with a ruler.

- measurement of electrical voltage with a voltmeter.

Indirect measurement

Indirect measurement- a measurement in which the desired value of a quantity is found on the basis of a known relationship between this quantity and the quantities subjected to direct measurements.

- the resistance of the resistor is found on the basis of Ohm's law by substituting the values of current and voltage obtained as a result of direct measurements.

Joint measurement

Joint measurement- simultaneous measurement of several non-identical quantities, to find the relationship between them. In this case, the system of equations is solved.

- determination of the dependence of resistance on temperature. At the same time, non-similar quantities are measured, and the dependence is determined based on the measurement results.

Cumulative dimension

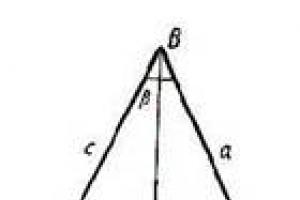

Cumulative dimension- simultaneous measurement of several quantities of the same name, in which the desired values of the quantities are found by solving a system of equations consisting of the resulting direct measurements of various combinations of these quantities.

- measurement of the resistance of resistors connected by a triangle. In this case, the resistance value between the vertices is measured. Based on the results, the resistances of the resistors are determined.

Wikimedia Foundation. 2010 .

See what "Direct measurements" are in other dictionaries:

DIRECT MEASUREMENTS- - measurements in which a measure or instrument is used directly to measure a given quantity ... Modern educational process: basic concepts and terms

Direct measurements of the change in the scaling factor of the PMF (differential attenuation of the variable attenuator)- Measurement of the power ratio at the output of the PMP (variable attenuator) with the help of IE with a perfectly stable generator 1 generator; 2 PMP; 3 ROI Source...

Direct measurements of the scaling factor of the PMF (transmission coefficient K P M- Measurement with the help of VPM of the power ratio at the output of a perfectly stable generator in the absence (P1) and in the presence (P2) between them of the PMF (calibrated attenuator) 1 generator; 2 PMF (attenuator); 3 VPM; Source … Dictionary-reference book of terms of normative and technical documentation

Direct measurement of power (or voltage) by VPM (or voltmeter)- 1 generator; 2 VPM or voltmeter Source ... Dictionary-reference book of terms of normative and technical documentation

Measurements serve to obtain an accurate, objective and easily reproducible description of a physical quantity. Without making measurements, it is impossible to characterize a physical quantity quantitatively. Purely verbal definitions of low or high ... ... Collier Encyclopedia

GOST R 8.736-2011: State system for ensuring the uniformity of measurements. Multiple direct measurements. Methods for processing measurement results. Key points- Terminology GOST R 8.736 2011: State system for ensuring the uniformity of measurements. Multiple direct measurements. Methods for processing measurement results. Basic provisions of the original document: 3.11 gross measurement error: Error ... ... Dictionary-reference book of terms of normative and technical documentation

Measurement error is the difference between measured and true or set value parameter. Source: NPB 168 97*: Fireman's carbine. General technical requirements. Test methods 3.11 measurement error deviation of a measurement result from the actual value ... Dictionary-reference book of terms of normative and technical documentation

measurement result- 3.5 measurement result: The value of a parameter obtained after a measurement has been made. Source: GOST R 52205 2004: Hard coals. Method for spectrometric determination of genetic and technological parameters ... Dictionary-reference book of terms of normative and technical documentation

the result of measuring a physical quantity; measurement result; result- the result of measuring a physical quantity; measurement result; result: The value of a quantity obtained by measuring it. [Recommendations on interstate standardization, article 8.1] Source ... Dictionary-reference book of terms of normative and technical documentation

gross measurement error- 3.11 gross measurement error: A measurement error that significantly exceeds the values of systematic and random errors that depend on the objective conditions of measurement. Source … Dictionary-reference book of terms of normative and technical documentation

Books

- Methods and means of measuring the speed of sound in the sea , I. I. Mikushin , G. N. Seravin , The book contains a systematic description modern methods and shipborne instruments for measuring the speed of sound in sea water. It discusses in detail direct methods for measuring the speed of sound - ... Category: Scientific and technical literature Publisher: Shipbuilding, Manufacturer:

Measurement method - a set of methods for using the principles and means of measurement.

A). The direct assessment method consists in determining the value of a physical quantity using the reading device of the measuring device direct action. For example, measuring voltage with a voltmeter. This method is the most common, but its accuracy depends on the accuracy of the measuring instrument.

B). Method of comparison with a measure - in this case, the measured value is compared with the value reproduced by the measure. The accuracy of the measurement may be higher than the accuracy of the direct estimate.

There are the following varieties of the comparison method with a measure:

Contrasting method, in which the measured and reproducible value simultaneously act on the comparison device, with the help of which the ratio between the quantities is established. Example: measuring weight with a balance scale and a set of weights.

Differential Method, at which the measuring instrument is affected by the difference between the measured value and the known value reproduced by the measure. In this case, the balancing of the measured value of the known is not completely performed. Example: voltage measurement direct current using a discrete voltage divider, a reference voltage source and a voltmeter.

Zero method, at which the resulting effect of the impact of both quantities on the comparison device is brought to zero, which is recorded by a highly sensitive device - a null indicator. Example: measuring the resistance of a resistor using a four-arm bridge in which the voltage drop across a resistor of unknown resistance is balanced by the voltage drop across a resistor of known resistance.

substitution method, in which the measured value and the known value are alternately connected to the input of the device, and the value of the measured value is estimated from two readings of the device, and then by selecting the known value, both readings are matched. With this method, high measurement accuracy can be achieved with a high accuracy of a measure of a known value and a high sensitivity of the instrument. Example: accurate accurate measurement of small voltage using a highly sensitive galvanometer, to which an unknown voltage source is first connected and the deviation of the pointer is determined, and then the same pointer deviation is achieved using an adjustable source of known voltage. In this case, the known voltage is equal to the unknown.

Match method, at which the difference between the measured value and the value reproduced by the measure is measured, using the coincidence of scale marks or periodic signals. Example: measuring the rotational speed of a part using a flashing strobe lamp: observing the position of the mark on the rotating part at the moments of the flashes of the lamp, the speed of the part is determined from the known flash frequency and the offset of the mark.

The types of measurements (if you do not divide them according to the types of measured physical quantities into linear, optical, electrical, etc.) include measurements:

- direct and indirect,

- joint and joint

- absolute and relative

- single and multiple

- technical and metrological,

- equal and unequal,

- equally scattered and unequally scattered,

- static and dynamic.

Direct and indirect measurements are distinguished depending on the method of obtaining the measurement result.

In direct measurements, the desired value of the quantity is determined directly by the device for displaying the measurement information of the measuring instrument used. Formally, without taking into account the measurement error, they can be described by the expression

where Q is the measured value,

Indirect measurements are measurements in which the desired value of a quantity is found on the basis of a known relationship between this quantity and the quantities subjected to direct measurements. Formal notation of such a measurement

Q = F(X, Y, Z,…),

where X, Y, Z,… are the results of direct measurements.

The measurement of a certain set of physical quantities is classified according to the homogeneity (or heterogeneity) of the measured quantities.

With cumulative measurements, several quantities of the same name are measured.

Joint measurements involve the measurement of several dissimilar quantities, for example, to find the relationship between them.

When measuring, to display the results, different evaluation scales can be used, including graduated scales either in units of the measured physical quantity, or in various relative units, including dimensionless ones. In accordance with this, it is customary to distinguish between absolute and relative measurements.

According to the number of repeated measurements of the same value, single and multiple measurements are distinguished, and multiple measurements implicitly imply subsequent mathematical processing of the results.

Depending on the accuracy of measurements, they are divided into technical and metrological, as well as equal and unequal, equally scattered and unequally scattered.

Technical measurements are performed with a predetermined accuracy, in other words, the error technical measurements should not exceed a predetermined value.

Metrological measurements are performed with the maximum achievable accuracy, achieving the minimum measurement error.

Evaluation of equiaccuracy and unequal accuracy, uniform scatter and unequal scatter of the results of several measurement series depends on the chosen limiting measure of error difference or their random components, the specific value of which is determined depending on the measurement task.

It is more correct to characterize static and dynamic measurements depending on the commensurability of the mode of perception of the input signal of the measurement information and its transformation. When measuring in a static (quasi-static) mode, the rate of change of the input signal is incommensurably lower than the rate of its conversion in the measuring circuit, and all changes are recorded without additional dynamic distortions. When measuring in dynamic mode, additional (dynamic) errors appear due to too rapid change the measured physical quantity itself or the input signal of the measuring information from a constant measured quantity.

The content of the article

MEASUREMENT AND WEIGHING. Measurements serve to obtain an accurate, objective and easily reproducible description of a physical quantity. Without making measurements, it is impossible to characterize a physical quantity quantitatively. Purely verbal definitions "low" or "high" temperature, "low" or "high" voltage are inadequate, since they do not contain comparison with known standards and, therefore, reflect only subjective opinions. When measuring a physical quantity, a certain numerical value is assigned to it.

Fundamental and derivative measurements.

Fundamental measurements include those on which a direct comparison is made with the primary standards of mass, length and time. (Recently, standards have been added to them electric charge and temperature.) So, the length is measured using a ruler or calipers, the angle using a protractor or theodolite, the mass using an equal-arm balance, etc. A number showing how many times the corresponding standard (or a multiple of it) "fits" in the measured value, and is a fundamental measure of this value.

Derived measurements include those in which secondary, or derivative, physical units, such as area, volume, density, pressure, velocity, acceleration, momentum, etc. The measurement of such derived quantities is accompanied by mathematical operations with basic, or fundamental, units. So, when measuring (determining) the area of a rectangle, first measure the base and height and then multiply them. The density of a substance is determined by dividing its mass by its volume (which, in turn, is a derived quantity). calculation average speed includes measurements of the distance traveled per unit of time. When performing derivative measurements, as a rule, instruments are used that are directly calibrated in terms of the quantities to be measured, which eliminates the need for any mathematical calculations. Thus, the corresponding mathematical equation is "contained" in the instrument itself.

Direct and indirect measurements.

Depending on the method of obtaining quantitative data, measurements are divided into direct and indirect. In direct measurements, the measured quantity is expressed in the same units as the standard used for the measurements. For example, on an equal-arm balance, an unknown mass is compared with a reference one, and an unknown length is determined with a ruler in terms of a reference one. On the other hand, the result of measuring the temperature with a thermometer is the height of the column of liquid filling the glass tube. This indirect method of temperature measurement assumes the existence of a linear relationship between the increments of temperature and the height of the mercury or alcohol column in the thermometer.

Indirect measurements are carried out with the help of sensors, which in themselves are not measuring instruments, but act as information converters. For example, a piezoelectric sensor made of barium titanate generates an electrical voltage by changing its dimensions under the action of a mechanical load. Therefore, by measuring this stress, it is possible to determine such purely mechanical quantities as deformations, moments or accelerations. Another strain gauge converts mechanical movement (elongation, contraction or rotation) into change electrical resistance. This means that by measuring the latter value, it is possible to indirectly, but with high accuracy, determine such mechanical characteristics as tensile compression forces or torsion moment. The electrical resistance of the cadmium sulfide photoresistor decreases when the sensor is irradiated with light. Therefore, to determine the amount of illumination perceived by the sensor, it is only necessary to measure its resistance. Some temperature-sensitive metal oxides, called thermistors, exhibit noticeable changes in electrical resistance with temperature. In this case, it is also sufficient to measure the electrical resistance to determine the temperature value. One of the types of flowmeters allows you to convert the number of revolutions of the rotor, rotating in a constant magnetic field, linearly related to it into the flow rate.

Linear and non-linear measuring devices.

Most simple type The measuring sensor is a "linear" device in which the output information (instrument reading) is directly proportional to the input information perceived by the device. As an example, consider an emission photocell (with an external photoelectric effect), which consists of two electrodes made of pure metals (one of them is photosensitive). The electrodes are enclosed in a glass vacuum tube and connected to a direct current source, the potential difference of which can be varied. A microammeter calibrated in units of illumination is connected to this device. Such a combined device is a photoelectric photometer, for which the measured value is light, and the output is electric current. The higher the illumination (with a constant potential difference on the electrodes), the more electrons emitted by the photocathode (negative electrode). The performance of this instrument is substantially linear over a wide range of illuminances and therefore has a uniform scale.

An example of a substantially non-linear instrument is an ohmmeter, which is used to measure electrical resistance in its own units (Ohm). The device contains a highly sensitive sensor electric current with a miniature battery and a protective resistor, which are connected in series. Since the current-resistance curve at constant voltage is a hyperbola, the relationship between the input and output values of this device is essentially non-linear. The scale of such a device will “shrink” in the range of high resistances (low currents). This instrument must be carefully calibrated before it is suitable for measuring unknown resistances.

Another example of a non-linear measuring device is a thermoelectric sensor (thermocouple). In an electrical circuit composed of two different metals, the joints (junctions) of which are maintained at different temperatures, a potential difference is created, which is the greater, the higher the temperature of the so-called. "hot" junction. However, if we study the dependence of the potential difference on temperature for a pair of metals iron copper, it will be found that the potential difference grows almost linearly only up to a temperature of 150 ° C; it reaches a maximum at 200°C and then decreases to zero at about 600°C. This measuring instrument also requires careful calibration (at several known temperatures and potential differences) in order to adequately exploit its non-linear response.

Measurement errors.

Systematic errors.

There are no perfect measurements. Even if the measuring equipment is designed and manufactured in the best possible way, it will still introduce certain systematic (constant) errors. The systematic errors include incorrect setting of the reference point, incorrect graduation of the instrument scale, errors caused by inaccuracy of the lead screw pitch or inequality of the lengths of the scale arms, errors due to gear backlash, etc. So, if you measure a certain length with a meter rod, which is actually a little less than a meter, all measurements of this length will contain a systematic error. You can live with this error, or try to reduce it by using a more advanced measuring device. However, in the case of gearboxes, for example, reducing the backlash in the engagement to a minimum value to reduce the systematic measurement error can lead to an increase in friction forces to such values that the gearbox cannot work.

Random errors.

There are also random errors. These include, for example, errors introduced by vibrations in laboratory research, transient processes in electrical circuits or thermal noise in vacuum tubes. Such errors cannot be predicted in advance and are difficult to estimate theoretically. Reducing the influence of random measurement errors is achieved by repeated measurements and (after discarding erroneous results) by calculating the average value.

observer errors.

Observer errors, or subjective errors, arise as a result of errors in the observer's assessment of the situation. Delay in starting or stopping the stopwatch, a tendency to overestimate or underestimate the results, errors in the interpretation of scales and deviations of the arrows, errors in manual calculations, etc. All these are examples of observer errors that affect the accuracy of determining the measured values. Since the results of measurements of the same value of a quantity are usually grouped around a certain central value, relative to which the deviations in one direction and the other are approximately the same, then from these results it is necessary to determine the average value, the probable error of a single measurement and the probable error of the calculated average values. Measurement results that deviate too far from the mean value are recognized as erroneous and discarded before the averaging procedure.

Errors due to external influences.

When working with secondary, or "working" standards, as well as with other measuring instruments, some specific errors may occur due to external influences. (Such errors are carefully controlled and reduced to a minimum in primary standards, which are stored with all precautions to ensure their invariance.) Thus, the value of a resistance standard available in the laboratory can be affected by changes in the humidity of the air or the frequency of the electric current passing through it, mechanical stress applied to the resistor. Measurements using a secondary capacitance standard can contain high-frequency errors, deviations due to dielectric losses and leakage resistance, and errors due to temperature changes. Instrumental errors include delay and hysteresis phenomena in aneroid barometers, excessively slow response of some Bourdon pressure gauges, etc. The experimenter must be aware of the specific errors to which his instruments are subject and take appropriate measures to correct or reduce the effects of these errors by improving the measurement technique or instrument design.